Crane outrigger pads

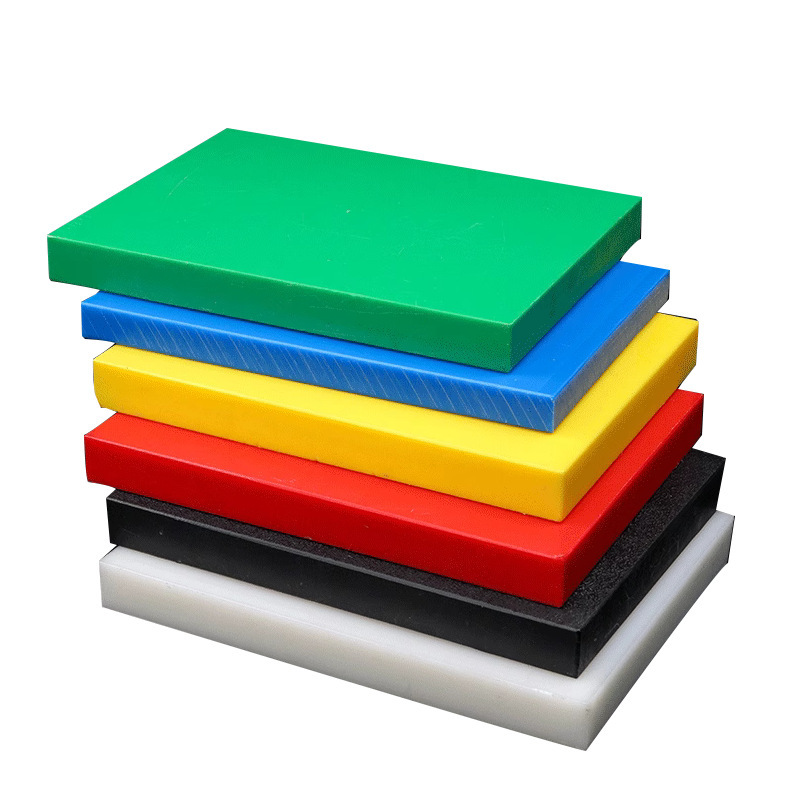

Leg pads are pads used to support heavy machinery and equipment. They consist of a plate-shaped pad body and a hand-held rope.

The leg pads are made of compressed UHMWPE/HDPE polymer composite. It can be used normally in harsh environments and will not be damaged when overloaded.

The hand-held rope is made of nylon, and the end of the hand-held rope is embedded in the pad body for easy transportation and use.

Phone/WhatsApp/WeChat

CATEGORY

HDPE (high-density polyethylene) leg pad is a pad used to support mechanical equipment.

Leg pads are mainly used to support the legs of construction machinery. Leg pads have high strength and stiffness, which can reduce the deformation of the pad body under stress and provide more stable support for construction machinery. Greatly saving usage costs and improving work quality.

Characteristic

● Strong load-bearing capacity: It can withstand heavy loads, such as placing the support legs of large equipment like cranes and excavators on top, and can stably distribute pressure to ensure that the equipment does not sink.

● Good wear resistance: Under frequent use, the surface will not be easily worn, and even after prolonged friction, it can maintain good performance, which helps to extend the service life of the pad.

● Excellent impact resistance: When the equipment generates vibration during operation or when the support legs are impacted by external forces, it can effectively buffer and reduce damage to the pad itself and the equipment.

● High chemical stability: It has resistance to many chemical substances and can prevent corrosion in work sites with acidic and alkaline chemical environments.

● Lightweight and portable: Compared to some traditional metal pads, HDPE leg pads are lighter in weight, easy to transport and move, and have more advantages when frequent job site changes are needed.

Purpose

● In the field of construction, it is used to support the legs of large construction equipment such as construction cranes and concrete pump trucks, ensuring stable operation of the equipment on soft or uneven ground.

● Logistics loading and unloading industry: used under forklifts and other loading and unloading equipment to improve the stability of the equipment during loading and unloading of goods and prevent equipment from tipping over.

● Petrochemical industry: provides stable support for the supporting parts of large-scale equipment such as oil extraction equipment and chemical towers, ensuring the safe operation of equipment.

Production Strength

The factory covers an area of approximately 15000 square meters and has introduced more than 30 advanced flat vulcanizing machines, injection molding machines, and CNC machining centers to produce products of different designs. The injection molding machine is equipped with an automatic robotic arm to improve production efficiency. With years of experience, we have produced a large number of successful molds and retained excellent molding tools for our customers through a better management system. All final products produced are shipped to various parts of the world.

|

|

|

|

Quality Assurance

The company has passed ISO 9001 quality management system certification and implements modern management of employees and production. We have experienced mold engineers who are familiar with international advanced design software. We serve many industries such as automobiles, electronic equipment, agricultural WI equipment, food and beverage machinery, mining machinery, textile machinery, and automated conveying equipment.

|

|

|

|

Get Free Consultation Information

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.