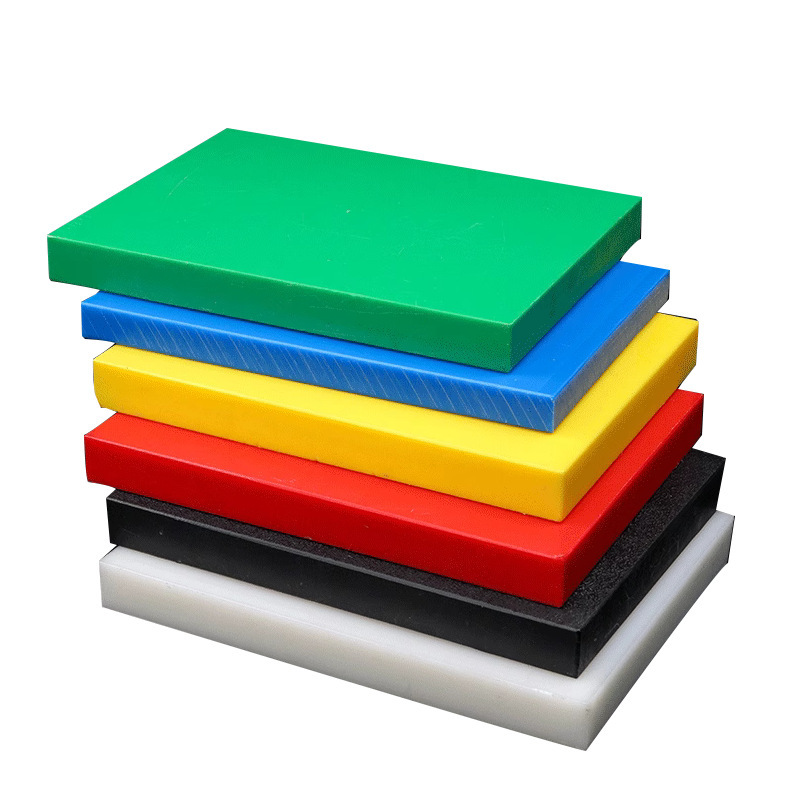

UHMWPE Ice Rink Panel

Phone/WhatsApp/WeChat

CATEGORY

A simulated ice rink is a facility that mimics a real ice skating rink.

Characteristic

● Easy installation: Compared to real ice rinks, it is not limited by site and environment, and does not require complex ice making equipment or a large amount of water resources. Whether indoors or outdoors, as long as the site is flat, it can be quickly installed and constructed, for example, it can be completed in a short period of time in places such as mall courtyards.

● Easy maintenance: No complex procedures such as ice making or sweeping. There is no need to worry about temperature changes causing the ice surface to melt, nor will water quality issues affect the quality of the ice surface. Basic cleaning work can keep the ice surface in good condition.

● Low cost: The construction of a simulated ice rink requires much less equipment, operation, and maintenance compared to a real ice rink, and does not require a refrigeration system or professional ice making maintenance personnel.

● Good safety performance: The material used to simulate ice surfaces usually has a certain degree of elasticity and friction, which can provide cushioning for skaters when they fall and reduce the risk of injury.

Purpose

● Commercial entertainment venues: Set up simulated ice rinks in shopping malls, supermarkets, amusement parks and other places for commercial performances, ice experience activities, etc., to attract customers and increase entertainment projects.

● Sports training: Basic training for beginners in ice skating. Skating courses in schools and communities can be conducted on simulated ice rinks without seasonal or regional restrictions, making teaching convenient.

● Private use: Install small simulated ice rinks in the courtyards or indoor spaces of some private residences for personal or family leisure and entertainment purposes.

Production Strength

The factory covers an area of approximately 15000 square meters and has introduced more than 30 advanced flat vulcanizing machines, injection molding machines, and CNC machining centers to produce products of different designs. The injection molding machine is equipped with an automatic robotic arm to improve production efficiency. With years of experience, we have produced a large number of successful molds and retained excellent molding tools for our customers through a better management system. All final products produced are shipped to various parts of the world.

|

|

|

|

Quality Assurance

The company has passed ISO 9001 quality management system certification and implements modern management of employees and production. We have experienced mold engineers who are familiar with international advanced design software. We serve many industries such as automobiles, electronic equipment, agricultural WI equipment, food and beverage machinery, mining machinery, textile machinery, and automated conveying equipment.

|

|

|

|

Get Free Consultation Information

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.