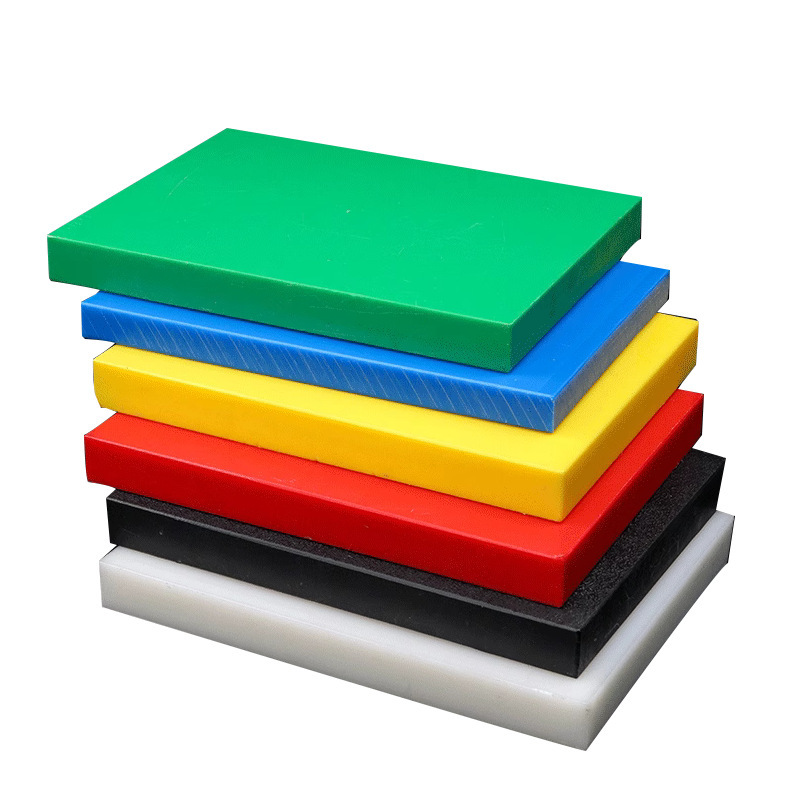

UHMWPE guide rail

UHMWPE guide rails are made of ultra-high molecular weight polyethylene

The material has superior comprehensive properties, including excellent wear resistance, good self-lubrication, good mute effect, high corrosion resistance, high impact resistance, good insulation properties, light weight, and strong processability.

Phone/WhatsApp/WeChat

CATEGORY

Characteristics of plastic guide rails

1. It has excellent self-lubricating and wear-resistant properties.

2. The friction coefficient of metal is small, which can reduce the driving force of sliding parts and improve transmission efficiency.

3. The static and dynamic friction coefficients are close (with little variation), making the sliding smooth; It can achieve extremely low non crawling movement speed while also improving the positioning accuracy of moving parts.

4. Due to its good self-lubricating properties, the lubrication device can be simplified, and occasional short-term interruptions in the lubricating oil will not cause damage to the guide rail.

5. The construction is simple, and the surface can be processed using general mechanical processing methods (milling, planing, grinding, manual scraping).

6. Due to the softness of plastic, occasional layer cutting and abrasive particles that fall into the guide rail can be embedded, resulting in strain on the metal guide rail surface.

7. Good repairability, when repairing, simply remove the old plastic layer and replace it with a new one.

Compared with other guide rails, it has a simple structure, low operating costs, good seismic resistance, low working noise, and high load-bearing capacity.

Production Strength

The factory covers an area of approximately 15000 square meters and has introduced more than 30 advanced flat vulcanizing machines, injection molding machines, and CNC machining centers to produce products of different designs. The injection molding machine is equipped with an automatic robotic arm to improve production efficiency. With years of experience, we have produced a large number of successful molds and retained excellent molding tools for our customers through a better management system. All final products produced are shipped to various parts of the world.

|

|

|

|

Quality Assurance

The company has passed ISO 9001 quality management system certification and implements modern management of employees and production. We have experienced mold engineers who are familiar with international advanced design software. We serve many industries such as automobiles, electronic equipment, agricultural WI equipment, food and beverage machinery, mining machinery, textile machinery, and automated conveying equipment.

|

|

|

|

Get Free Consultation Information

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.