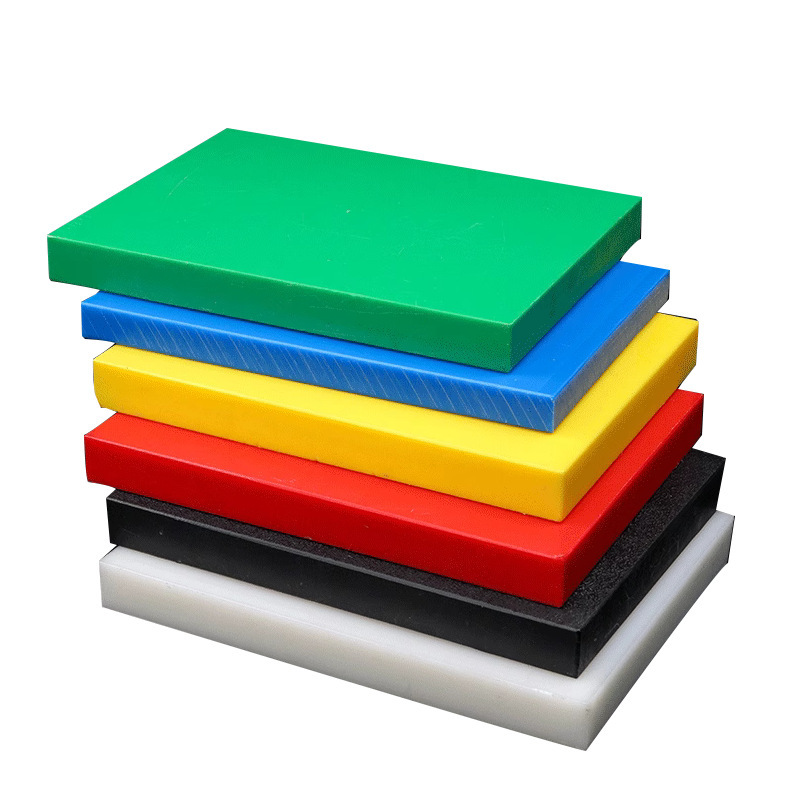

ABS rod

Phone/WhatsApp/WeChat

CATEGORY

Characteristic

● Good comprehensive performance: ABS rods have the characteristics of toughness, hardness, and good rigidity. It combines the hardness of acrylonitrile, the toughness of butadiene, and the processability of styrene, and can withstand certain pressure and impact forces.

● Good chemical corrosion resistance: it has a certain tolerance to water, inorganic salts, alkalis, and various acids, but it is not resistant to certain organic solvents such as ketones and aldehydes.

● Excellent processing performance: It can be easily made into various shapes through mechanical processing (such as cutting, drilling, milling, etc.), and the material properties will not be greatly affected during the processing.

● Excellent appearance performance: The surface is smooth and glossy, and can be treated with coatings, electroplating, and other surface treatments to achieve better appearance effects.

Purpose

● Mechanical manufacturing: used to manufacture various mechanical parts such as gears, bearings, etc., utilizing their excellent mechanical properties to ensure the normal use of the parts.

● Automotive industry: widely used in automotive interior and exterior parts. For example, interior parts such as the dashboard and door trim panels, as well as exterior parts such as the bumper of a car, can all be made of ABS rods.

● In the field of electronic appliances: used for making electrical enclosures, sockets, switches, etc. Due to its insulation and ease of processing, it can meet the design and production requirements of electrical products.

● Toy manufacturing: Due to its good comprehensive performance, easy processing and shaping, and attractive appearance, it is often used to make the main structure or various toy parts.

Production Strength

The factory covers an area of approximately 15000 square meters and has introduced more than 30 advanced flat vulcanizing machines, injection molding machines, and CNC machining centers to produce products of different designs. The injection molding machine is equipped with an automatic robotic arm to improve production efficiency. With years of experience, we have produced a large number of successful molds and retained excellent molding tools for our customers through a better management system. All final products produced are shipped to various parts of the world.

|

|

|

|

Quality Assurance

The company has passed ISO 9001 quality management system certification and implements modern management of employees and production. We have experienced mold engineers who are familiar with international advanced design software. We serve many industries such as automobiles, electronic equipment, agricultural WI equipment, food and beverage machinery, mining machinery, textile machinery, and automated conveying equipment.

|

|

|

|

Get Free Consultation Information

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.