Marine fender pads

Phone/WhatsApp/WeChat

CATEGORY

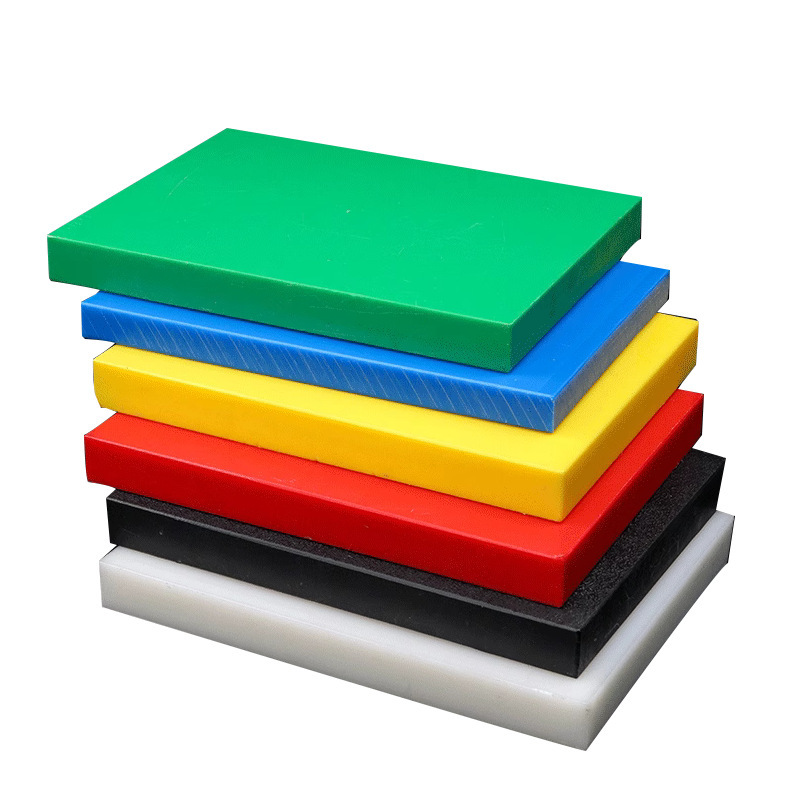

Ultra high molecular weight polyethylene ship mudguards and dock impact plates have excellent wear resistance, impact resistance, self-lubricating properties, chemical corrosion resistance, low temperature resistance and other characteristics, which are the highest values among existing plastic varieties. The wear resistance is 3-7 times that of carbon steel and stainless steel; Low friction coefficient, self-lubricating, non absorbent, non adhesive material, high impact resistance and strength, good comprehensive mechanical properties, acid and alkali resistance, salt corrosion resistance, non aging, low temperature resistance, hygiene and non toxicity, light weight, with a specific gravity of 1/8 of steel. It has a wide range of applications,

Performance

1. The wear resistance of dock fender panels ranks first among plastics, and the higher the molecular weight, the higher the material's wear resistance and impact resistance.

2. The impact strength of the dock fender panel is the highest among existing plastics, and it still has a considerable impact strength even at -70 °C.

3. Very good self-lubricating properties.

4. The water absorption rate of the dock fender panel is extremely low. Therefore, its physical and mechanical properties are independent of humidity factors in the working conditions used.

5. The chemical stability of the dock fender panel is stable, and it can withstand corrosion from various corrosive media such as acid, alkali, salt, and organic solvents within a certain temperature and concentration range; 6. The dock fender panel is odorless, non-toxic, odorless, non corrosive, and has physiological circulation and adaptability.

7. Non adhesiveness.

8. When the molecular weight of the dock fender panel exceeds 500000, the embrittlement temperature drops to -140 ° C. The dock fender panel can even be used at temperatures below -269 ° C under the action of liquid nitrogen, and still has a certain mechanical strength.

Production Strength

The factory covers an area of approximately 15000 square meters and has introduced more than 30 advanced flat vulcanizing machines, injection molding machines, and CNC machining centers to produce products of different designs. The injection molding machine is equipped with an automatic robotic arm to improve production efficiency. With years of experience, we have produced a large number of successful molds and retained excellent molding tools for our customers through a better management system. All final products produced are shipped to various parts of the world.

|

|

|

|

Quality Assurance

The company has passed ISO 9001 quality management system certification and implements modern management of employees and production. We have experienced mold engineers who are familiar with international advanced design software. We serve many industries such as automobiles, electronic equipment, agricultural WI equipment, food and beverage machinery, mining machinery, textile machinery, and automated conveying equipment.

|

|

|

|

Get Free Consultation Information

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.