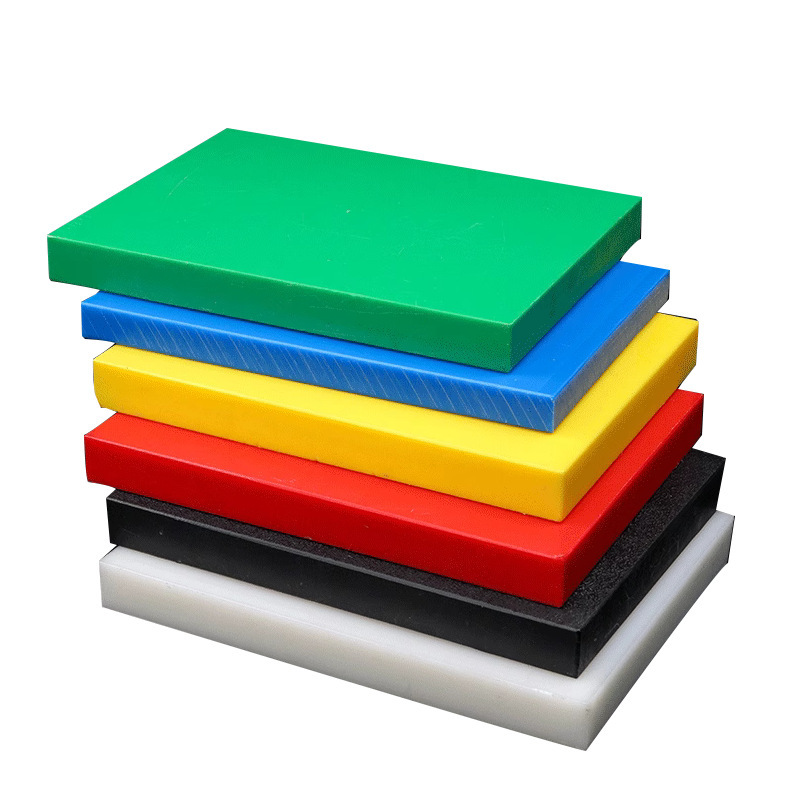

Polyethylene board

Phone/WhatsApp/WeChat

CATEGORY

Characteristics and Applications

Polyethylene board has the characteristics of light weight, uniform thickness, smooth and flat surface, good heat resistance, high mechanical strength, excellent chemical stability and electrical insulation, and non toxicity. PP board is widely used in fields such as chemical containers, machinery, electronics, electrical appliances, food packaging, medicine, decoration, and water treatment. PP board is a low-density extruded material. It is sturdy, highly rigid, and hard. It has low water absorption and good chemical resistance to acids, bases, and organic solvents. The mechanical strength, impact resistance, and thermal/electrical insulation properties of this material make it a popular material in various industries. Due to FDA approval, it is commonly used in the chemical industry as a lining for acid and chemical tanks or in the food manufacturing industry. The recommended temperature range for use is -20 ° C to+80 ° C. Polypropylene is easy to form and weld, but may become brittle at lower temperatures.

Application scope

Chemical equipment, water treatment components, seals, insulators, ventilation ducts, cargo pallets, drip trays, acid and alkali resistant equipment, environmental protection equipment, wastewater and exhaust gas discharge equipment, washing towers, clean rooms, semiconductor factories and related industrial equipment, anti-collision doors and wall panels. PP sheet also has good thermal and electrical insulation properties, and is resistant to various acids, alkalis, and organic solvents. It is an ideal choice for manufacturing operations in chemical and wastewater treatment plants, and is also the preferred material for manufacturing plastic water tanks. Among them, PP thick sheet is widely used in stamping plates, punch press pads, etc.

Main features

● Temperature:- 20 ° C to+80 ° C

● Extremely low water absorption and low density, has excellent tolerance to dilute acids, cleaning agents, and various solvents.

● Easy to process, shape, and weld.

● FDA approval.

● Good heat resistance and can maintain good strength at 100 ℃. Good chemical corrosion resistance, acid and alkali resistance, reliable electrical insulation performance, high mechanical strength, non-toxic, and excellent chemical stability

| Size and color | ||

| Color | Sheet size (mm) | Plate thickness (mm) |

| White/Black | 1000×1000 | 2-30 |

| White/Black | 2000×1000 | 2-30 |

| White/Black | 3000×1000 | 2-30 |

| White/Black | 4000×1000 | 2-30 |

| For other colors, yellow, blue, red, and green are all available. | ||

Production Strength

The factory covers an area of approximately 15000 square meters and has introduced more than 30 advanced flat vulcanizing machines, injection molding machines, and CNC machining centers to produce products of different designs. The injection molding machine is equipped with an automatic robotic arm to improve production efficiency. With years of experience, we have produced a large number of successful molds and retained excellent molding tools for our customers through a better management system. All final products produced are shipped to various parts of the world.

|

|

|

|

Quality Assurance

The company has passed ISO 9001 quality management system certification and implements modern management of employees and production. We have experienced mold engineers who are familiar with international advanced design software. We serve many industries such as automobiles, electronic equipment, agricultural WI equipment, food and beverage machinery, mining machinery, textile machinery, and automated conveying equipment.

|

|

|

|

Get Free Consultation Information

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.